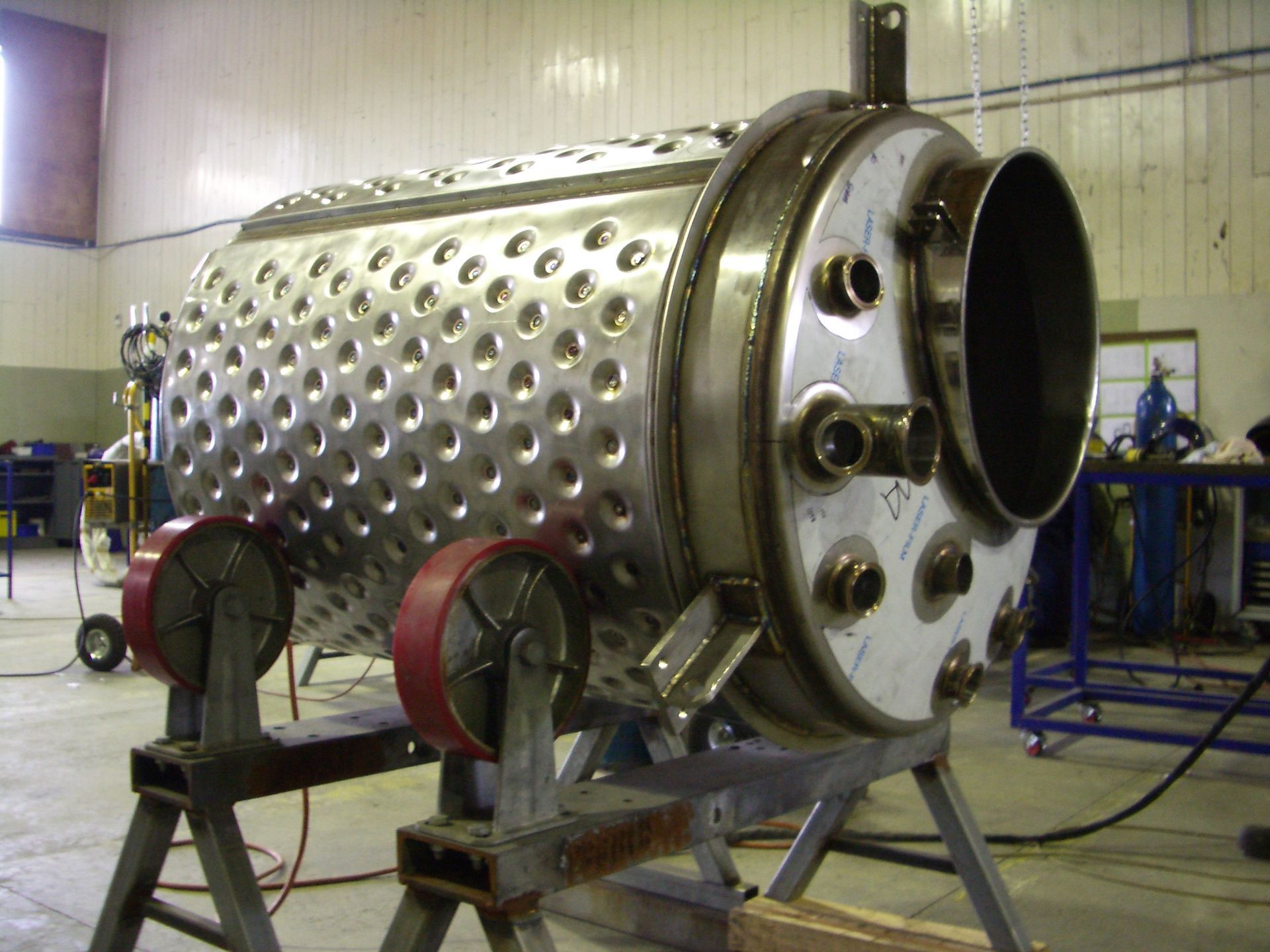

Explore Our Comprehensive Stainless Steel Fabrication Capabilities for New Zealand Clients

Based in Hamilton, Waikato, Protech Stainless Ltd provides extensive stainless steel fabrication capabilities to clients throughout New Zealand and, in some cases, Australia. With over 150 years of combined experience, our team offers high-quality fabrication and installation services across industries such as dairy, food and beverage, marine, and councils. Our modern 1600 m² workshop and skilled operations team ensure that no matter the scale or complexity of your project, we have the capability, tools, and expertise to deliver exceptional results with reliability and precision.

Advanced Fabrication Machinery and Workshop

Our workshop is designed to serve complex stainless steel fabrication needs, making us a strong partner for serious projects. With four bays in our facility, we are able to handle fabrication, assembly, and finishing all under one roof. We maintain and upgrade our equipment to ensure precision, safety, and quality of output on every job. Our in-house capacity means faster turnarounds, full control over quality, and consistent delivery for our clients.

Workshop: Four Bays

- 1600 m² of workshop floor

- Two 5-tonne and one 3-tonne monorail cranes 8.1 m under the hook

- Two 5-tonne and two 3-tonne monorail cranes 7.2 m under the hook

- 3-tonne and 1.8-tonne forklifts

Press Brake

- 2 × press brakes available

- Baykal APH 3106×120

- 120-tonne pressing capacity up to 3100 mm in length

Plate and Sheet Rollers

- Fintek HR 0810 2500 mm × 10 mm

- Pyramid 3 roll type with camber design

- Cone Rolling

- Lateral and Overhead Roller Supports

Sheet Rollers

- Sahinler IRM 1550 mm × ø140 mm Pinch Rolls

- 4 mm stainless steel max

Sectional Rolls

- Sahinler HPK 80

- Angle, T, Channel and Flat Bar

- Pipe and tubular sections possible

Variable Rake Guillotine

- Machtech AGS 3108

- 3100 mm × 8 mm mild steel and 6 mm stainless steel

- Motorised Back Gauge

Knuckling Rolls

- Knuckling up to 350 mm in diameter

- Max sheet thickness: 3 mm stainless steel

- Inner Knuckle Radius 20 mm

Vessel Rollers

- Thirteen 6-tonne vessel rotators ø160–4000 mm

- Two 3-tonne vessel rotators ø40–1400 mm

- Rotating Table

Welding Tables

- One Demmeler Welding Table 3000 × 1500 mm

- Two Demmeler Welding Tables 1500 × 1500 mm

- One BuildPro Welding Table 1100 × 800 mm

Beam Welder

- 2 mm to 10 mm material thickness

- Up to 2600 mm long component capacity

Tube-to-Tube Orbital Welding

- 25.4 mm (1″) to 101.6 mm (4″) Tube

- Orbiweld 115 series with extra-thin weld heads

- 300 A Power Supply with High Duty Cycle

Tube to Plate Orbital Welding

- 10 mm ID tube up to 78 mm OD tube

- Orbital weld head with cold wire feeding

- 300 A Power Supply with High Duty Cycle

Bead Blasting

- 5800 mm × 2300 mm booth

- Longer lengths possible

GF Saws

- Three 101.6 mm (4″) orbital tube and pipe cutting saws

- One 203.2 mm (8″) orbital tube and pipe cutting saw

The range and scale of our machinery mean we can treat any project, from small custom parts to large industrial tanks and skids, with the same level of care and thoroughness.

Any Fabrication Project of Any Size

At Protech Stainless, we believe in delivering excellence, whether a project is modest or large-scale. All projects, big or small, benefit from our full-service model, experienced tradespeople, and high-capacity workshop. For large and complex projects, we also offer on-site assembly and installations, bridging the gap between workshop build and operational deployment. This versatility makes us a go-to partner for clients in the dairy, food processing, marine, architectural, and infrastructure sectors.

Why Choose Protech Stainless Ltd?

Choosing Protech Stainless means partnering with a company that has robust capabilities, proven experience, and a commitment to quality. Our workshop size, machinery portfolio, and experienced team set us apart in the stainless steel fabrication industry across New Zealand. We prioritise communication, transparency, and delivering on schedule while maintaining high standards of safety and workmanship. Whether your fabrication needs are routine or highly specialised, you can rely on us to deliver performance, reliability, and value.

Frequently Asked Questions

What scale of stainless steel fabrication projects can you handle?

We have a 1600 m² workshop, multiple cranes and heavy-duty rollers and welding machinery, enabling us to manage large and complex fabrication jobs.

What types of materials and grades do you work with?

We work primarily with stainless steel (grades such as 304, 316, and duplex) and utilise specialised welding and finishing processes to meet industry-specific requirements.

Do you offer on-site assembly and installation for larger projects?

Yes — for projects that are too large to transport in one piece, we fabricate modules in our workshop and then assemble and install them on-site with specialist transport and lifting equipment.

How do you ensure quality and compliance for fabrication projects?

We maintain strict quality control protocols across all machining, welding, and finishing operations and adhere to relevant industry standards to guarantee reliable, safe, and high-performing fabrications.

Want to learn how our workshop and capabilities can support your next project? Contact Protech Stainless Ltd today for expert guidance and tailored solutions.